Our services

From consultancy to production: technology is at the service of the people

To offer our customers excellent services and create original projects tailored to the specifics of each individual order, we focus on: harmony, serenity, coordination, and collaboration of all Grafica Atestina team.

We are 50 specialists, trained and motivated, who work with updated and cutting-edge tools and equipment to offer the best service. Everyone enriches the final product with their own skills.

The combination of a professional team and cutting-edge systems create value for our company and make our products unique.

Design and Consulting

It is a dynamic experience: we listen to our customers and guide them through the various technical and material proposals. To the creative aspect we add the skills of our R&D office on processes, shapes, resistance characteristics and use. Everything becomes possible, and to facilitate product visualization, we can create prototypes and samples to test before industrializing the entire process.

Prepress

We verify the correct preparation of the file for printing, intercepting any anomalies and carry out the most convenient and suitable "machine drop" for the job. We provide the blueprint and the colour proof as "Seen for printing".

To do this we make use of GMG Color Lab workflow systems for colorimetric control, UGRA/FOGRA 39L and 47 contractual colour proofing, capable of certifying four-colour process and simulating lamination, in-process control in compliance with ISO 12647, machine linearisation offset.

The printing systems are created with the Kodak CTP system (Computer to Plate) using rulings up to 200 lpi, stochastic screens for maximum accuracy in image reproduction. We use plates without the need for chemical substances for development (process free).

Press

We are equipped with rigorous operating standards (X-rite supplied on all machines), which translate into high accuracy in colour reproduction in both four-colour and Pantone.

The printing machines are connected to the pre-press department and to the company management system to constantly check the progress and performance of the processes.

We guarantee colour uniformity in reprints even for orders made over time and we also have a colour mixing station to reproduce the most demanding recipes. We also print and gloss at the same time.

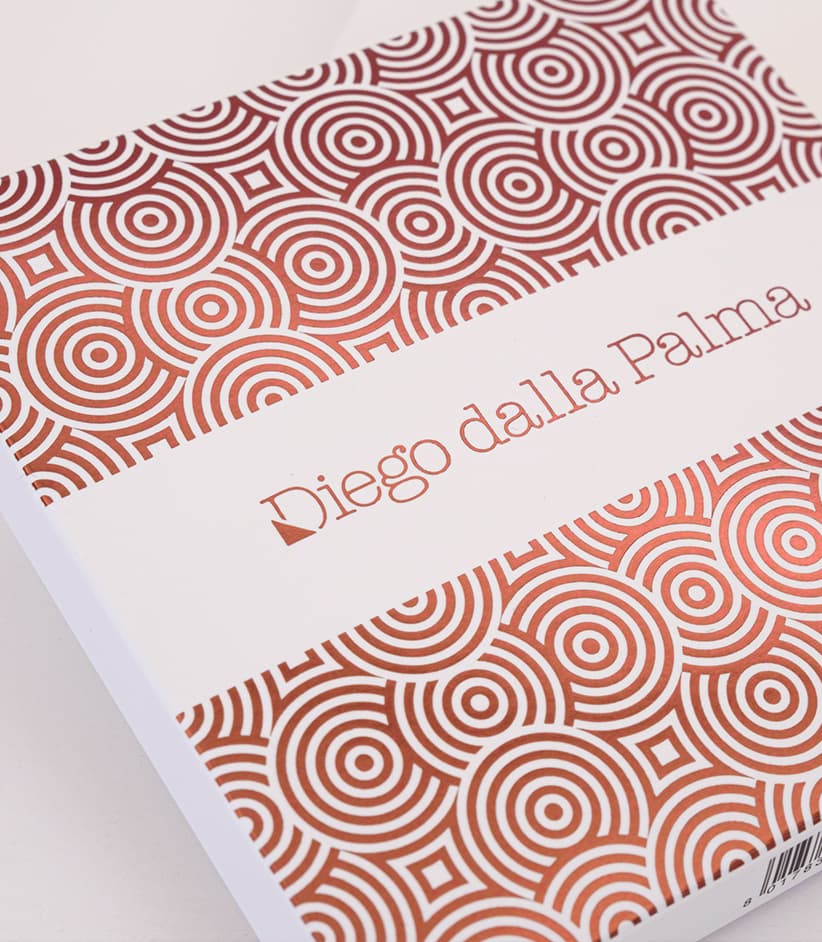

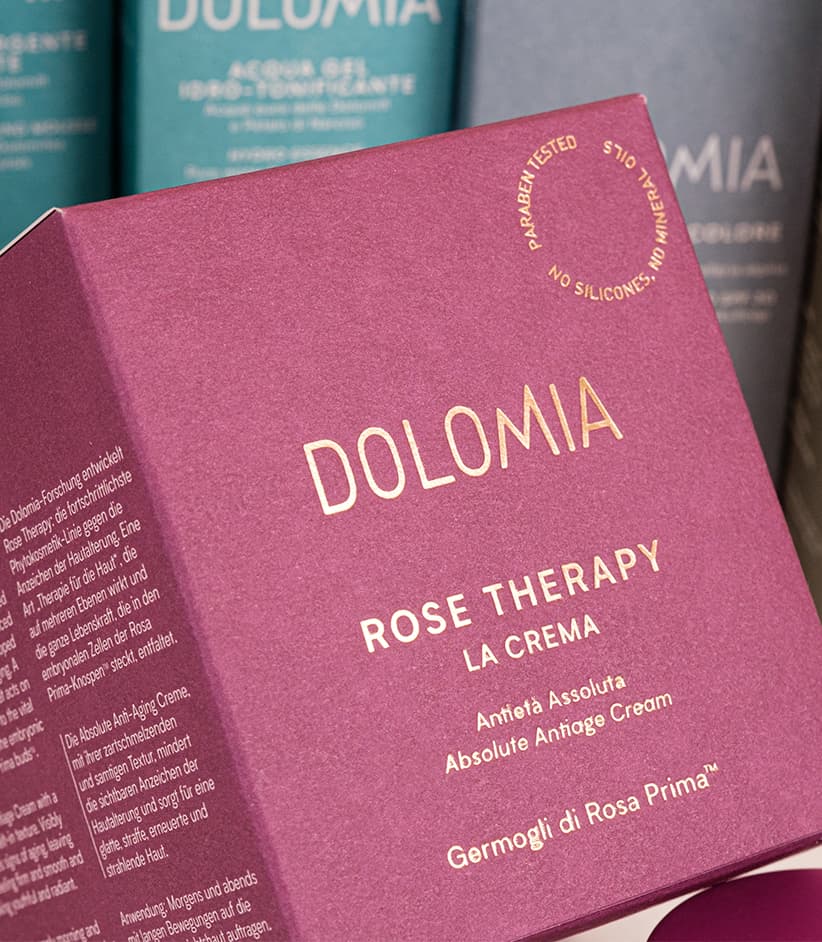

Finally, we can embellish the printed work with the most varied finishings: glossy, matt or soft-touch lamination, hot gold and silver, silk-screen UV varnish.

- Heidelberg Speed master, 72x102 4 colours with double side printing

- Mitsubishi V3000, 75x105 5 colours with painting system and oven

Bookbinding

The important thing is to take the right turn! Finishing with dedication and care requires great technical and manual skills and extreme precision.

We create staple bindings and parallel or cross folds even for minimal formats, thanks to advanced technology. We work in separate stations and each system is equipped with code reading with in-line cameras to avoid mixing.

- Polar 137 70x100 cutter, with automatic stack loading and unloading system

- Muller Martini stapler, with double central cut for minimum formats

- MBO 70x100 folder, 4 pockets and 4 blades

- Guk FA 50/6+6 folding machine 6 pockets+6 pockets second group + blade

- Guk FA 36/8 folder, 8 parallel pockets

- Guk FA 36/6+2 folder, 6 pockets + 2 second group pockets

- Guk 25x35 folder, 4 pockets for parallel folds

- Guk 51 10/6 folder, 10 pockets + 6 pockets according to group

- Guk S250 folder, 55x100, 10+6 pockets and blade with water creasing system

Paper conversion

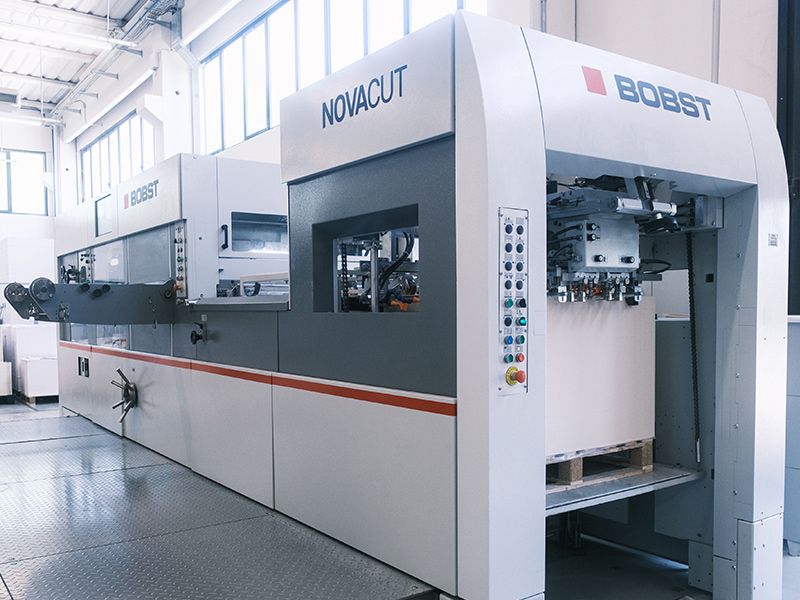

The die-cutting service is carried out with flat dies and extractor for greater shaping and cutting precision.

We can also make Braille punches and dry embossing.

The subsequent folder-gluing phase allows us to glue linear bottoms, snap-on bottoms, self-assembling bottoms, with internal separators and finally, curb bottoms in a single step thanks to girobox devices.

All finishing lines are equipped with cameras and automatic expulsion of non-standard items.

- Bobst Novacut 106 die cutting machine with extractor

- Bobst EXPERTFOLD 110 A2 folder gluer with girobox. This machine allows the gluing of curb bottoms and horizontal and vertical flaps in a single pass

- VisionFold folder gluer for linear cases

Packaging

Within the packaging division we assemble cases or boxes, and manually assemble and glue everything that cannot be mechanized.

Furthermore, upon request, we insert your products or product testers inside the pack and apply the batch number. We individually package display kits to deliver the complete product to the customer, ready to be shipped to the points of sale.

Logistics

Only after the final check does the logistics department come into play by managing the storage, ensures batch traceability and coding.

Our drivers will personally carry out the delivery with company vehicles, to ensure the pre-established dates and the integrity of the goods.

Our work

Since 1954 we have been offering our experience to our customers for the production of unique products.

Find out what we can do for you.